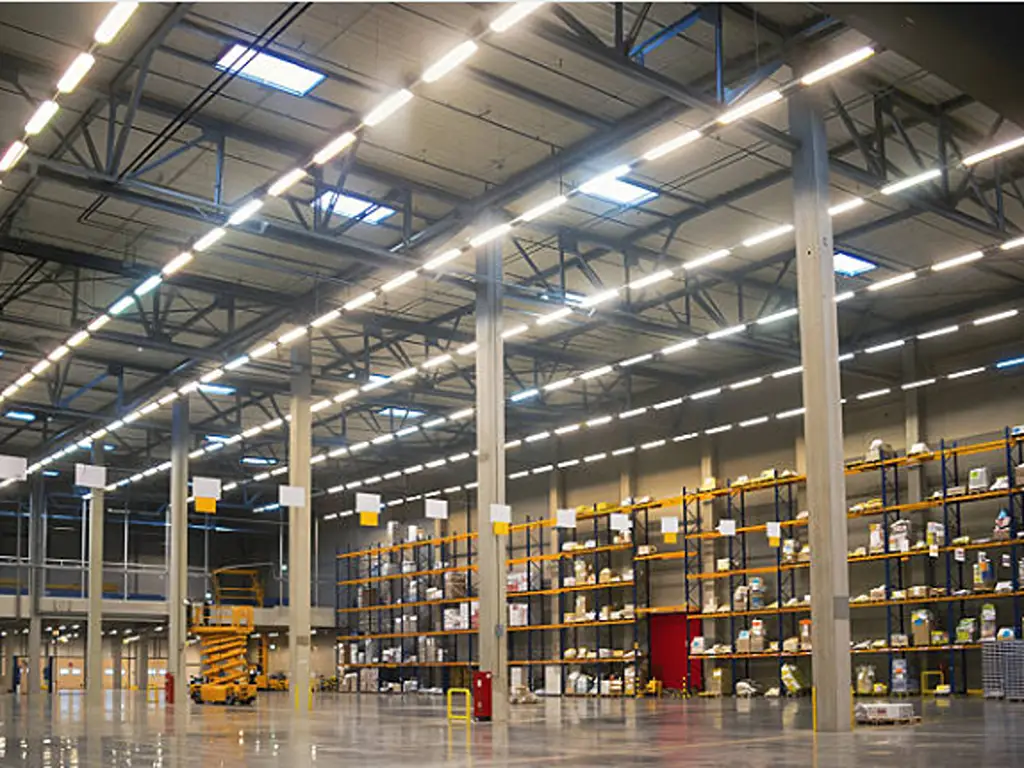

The future of logistics lighting control systems in the year 2026 does not involve simply the hanging of a lamp in the warehouse. It has become an advanced systemic engineering project; which bridges the relationship between electricity overheads, labour ergonomics and a progressively high degree of safety compliance. An effective installation of led lighting nowadays is a direct measure of the competitive advantage of a facility. Since the global supply chains require greater throughput, the quality of your illumination platform is the soundless engine that generates accuracy in operations, employee health and long-term savings of assets.

Understanding Essential Lighting Standards and Lux Levels

Creation of the correct standards in terms of functional zones is the first step towards the installation process of professional illumination. The right lighting ensures that the Lux (lx) and the Color Rendering Index (CRI) are used in the industrial context as indicators of success.

The Science of Lux in Warehouse Zones

- Aisles and Corridors: These transition areas typically need 100-150 Lux so that they can be safely navigated as well as allow movement of forklifts, which best suits the requirement for preventing collisions in busy intersections with low bay lighting.

- Storage Racks: Here the emphasis is laid on vertical factory lighting for large industrial spaces. At least 200 Lux is needed to make barcodes, SKU numbers, and labels visible on the floor to the top level (usually more than 12m), which is critical in minimizing picking mistakes.

- Picking and Packing Zones: This is a high activity area with high ceilings that needs 300 Lux or higher. Tasks involving fine details, e.g. reviews of shipping manifests, inspection of product integrity, etc., are reliant on this greater intensity to reduce the error rate of sorting and eye strain, making it the best choice for efficient operations.

- Loading Docks: These are transition zones that are of high contrast. An important factor to synchronise the high natural light level outside with the ambient light of the inside to avoid temporary visual blindness by forklift drivers is that they require about 150-200 Lux, which can be enhanced with the use of linear high bay lights.

Why Color Rendering Index (CRI) Matters

Color Rendering Index (CRI) is a decisive aspect in the contemporary warehouse settings because it determines the extent to which a source of light appears to give the actual color of objects in comparison to the natural sunlight. Color temperature and CRI of 80 or more, which has been adopted as an irrevocable standard in the 2026 industrial standard, should be seen as a means of reducing cognitive fatigue among workers since high color fidelity would greatly ease the workload on the employee, especially in harsh conditions where lighting quality is critical.

Color contrast within a warehouse environment gives warehouse staff an easy time in differentiating between color-coded labels, small text descriptions, and complicated SKU numbers when working in a challenging 10-to-12-hour shift. This is not just lowering the rate of picking error but making the lighting solutions system, it is not a mere utility but a precision asset, which is optimizing the visual ergonomics, increasing the processing speed, and improving overall energy usage.

Choosing the Right Fixtures for Your Ceiling Height

Other than to establish the right Lux standards, the physical architecture of your warehouse determines the complexity of the installation engineering. The composition of the composition is largely dependent on the size and height of the ceiling of the center. Usually, lamps and light-bulbs of low power at 15 meters clearance will put the floor full of unsafe shadowy spots and excessively high power lights at the wrong places will cause glare blindness and massive wastage of power. The choice of lighting must be scientifically modified to the vertical area of the place in order to achieve the best synergy in the quality of the light and the expense involved.

Low Bay and Surface-Mounted Fixtures

The standard lighting fixtures are Low Bay fixtures in facilities whose ceilings are less than 6 meters and comply with safety standards. These normally have a broad beam size of about 120deg in order to cover a given area in a restricted vertical area. In low-clearance zones, the design consideration is placed on visual comfort so that employees will not feel discomfort when being directly exposed to the high-intensity lights when picking or packing goods.

The Performance of UFO and Linear High Bays

The physical properties of light throw are the greatest challenge when the height is beyond 10 meters. UFO High Bays, equipped with metal halide fixtures for enhanced brightness, having better die-cast aluminum heat sinks and 360 degree covering are the perfect workhorses of open distribution centers, helping to reduce energy costs. On the other hand, Linear High Bays are the experts with high-rack aisles, which create a rectangular beam, which perfectly fills the corridor, ensuring maximum vertical Lux, so that all items on the upper rack to the bottom rack are brightly lit.

The Role of Vapor Tight Fixtures

Vapor Tight (Tri-proof) fixtures are necessary in cold storage rooms, high-humidity loading bays, and provide various lighting options for dusty workshops, etc. These fixtures have a design that uses a hermetically sealed design to avoid intrusion of moisture and dust into the internal circuitry. Vapor Tight fixtures can be used successfully to eliminate the advent of condensation, especially on cold storage facilities where temperatures change between 20 degrees centigrade (37 degrees Fahrenheit) and 60 degrees centigrade (125 degrees Fahrenheit), to facilitate operational safety with IP65 or IP66 protection specification., including options for new warehouse lighting.

Safety Protocols and Mechanical Installation Methods

Not only electrical connection is involved in installation, but also long term structural security in a high vibration manufacturing location.

Secure Mounting: Pendant vs. Surface Mount

The mounting is to be determined by the architecture of the building and airflow in the environment, particularly when considering commercial lighting options.

- Pendant (Chain) Mount: This is best used when the ceiling of the room is very high. It enables the ambient air to enclose the fixture, which helps in the heat dissipation through the conduction of the air. Caution Stabilizers or rigid pendants are required to eliminate the so-called swinging effect of strong HVAC systems or ceiling fans of large size.

- Surface Mount: The surface mount was commonly employed in places where there was little vertical clearance or where the ceiling construction (e.g. concrete slabs) could not support the suspension.

- Hook Mount: The most used and convenient type of I-beam structure. The most important process is that we need to assure the locking screw of the hook is completely in place so that it cannot be knocked off by vibration of the building or resonance of heavy machines.

Impact Resistance and IK Rating Standards

The Forklift Factor is a danger on warehouse operations that is common and frequently overlooked. It is extremely prevalent in high-speed picking or high-tier lifting that the forklift masts or pallet loads will collide with proper lighting overhead.

- IK Rating: This is an international standard (IK01 to IK10) which describes the ability of an enclosure with respect to its capability to stand various kinetic energy.

- Requirement: IK08 to IK10 rating is needed in any place where there is some form of mechanical operation. These fittings use high strength alloys of aluminum casings and tempered or high impact polycarbonate lenses.

The manufacturing heritage and use of high tolerance engineering directly give a structural integrity of a given fixture. A really amazing system is not a mere source of light, but a protector of your working process. The decision that is strong today is the one on uniting with a manufacturer that has high standards that ensure that minor accidents are not turned into disasters of an operational nature. There is only one way to a really future-proof facility which is to leave your infrastructure to industry proven expertise.

Maximizing Energy Efficiency Through Optical Precision

The gains in energy efficiency in 2026 will be dependent not as much on the raw lumen efficiency of the LED chip but rather on optical accuracy that meets the specific needs of different applications. The fixtures of this type have very accurate lenses, shaping beam angles (30 °, 60 °, or 90 °) with great accuracy, and all the lumens are focused on the floor or the rack face instead of being wasted on dead wall space or ceiling corners.

This directional targeting has the advantage that managers are now able to obtain the same measured Lux levels with lower-wattage (e.g. 150W) high-end fixtures as with generic 200W fixtures. This optical care, over the long term, will reduce monthly power expenses by large figures, significantly lowering energy consumption and can save a facility tens of thousands of dollars in operation expenses within a few years.

Planning for Long-term Maintenance and Heat Dissipation

Although LEDs can withstand heat, heat is its biggest enemy, affecting the bottom line. Your installation life will be determined by the effectiveness of the system to handle the thermal loads.

- Thermal Management: The heat sink design must be highly robust in order to avoid the problem known as lumen depreciation- the gradual drop in brightness of the LED as the lifespan of the LED reaches 50,000 to 100,000 hours. Exact thermal control maintains the core junction temperature at low value and keeps the semiconductor intact and the brightness maintained over the years.

- Maintenance ROI: Good quality heat dissipation will lead directly to the reduction of the number of high-altitude maintenances. The true price of a lamp is not in a busy warehouse, it is the logistics. Each failure necessitates the hiring of a scissor lift and blocking active aisles that lead to bottlenecks in operations that hugely outweigh the cost of the actual fixture itself.

Project Timing and Supply Chain Synchronization

Due to delays in delivery, a setback in terms of productivity can occur during warehouse construction, which is often not a technical barrier but rather a downtime related to industrial lighting design. All the engineering nodes are linked and the delayed delivery of the lighting system will directly impact the delay of later floor covering, rack inspection, and the eventual start of the operations. In order to have the project running as scheduled, it is of paramount importance to select a partner who has a rich manufacturing background and has established logistical control.

In order to close this divide between planning and execution, WOSEN uses its industrial capabilities to transform logistics issues into certainty in an orderly manner.The high quality of the aluminum alloy material that can be supplied by a large-scale automated production line by WOSEN, which has long maintained control over its quality, is capable of delivering an immensely reliable delivery cycle in 35-45 days. This comprises of highly machined fixtures that are rated IK10 Impact Resistance rating–the highest industrial requirement of hardiness against mechanical impacts. This stability in the supply chain enables the project managers to plan labor and equipment rentals to the minute, avoiding the penalty of dark sites.

WOSEN was able to deliver IP65-rated high-durability fixtures, including metal halide options, on time, as was observed during the successful installation of one of the largest warehousing projects in Canada, and this aspect of the company transformed what would have been a deficit in the supply chain into a competitive edge, with the facility opening in time to be operational during the global shopping peak season.

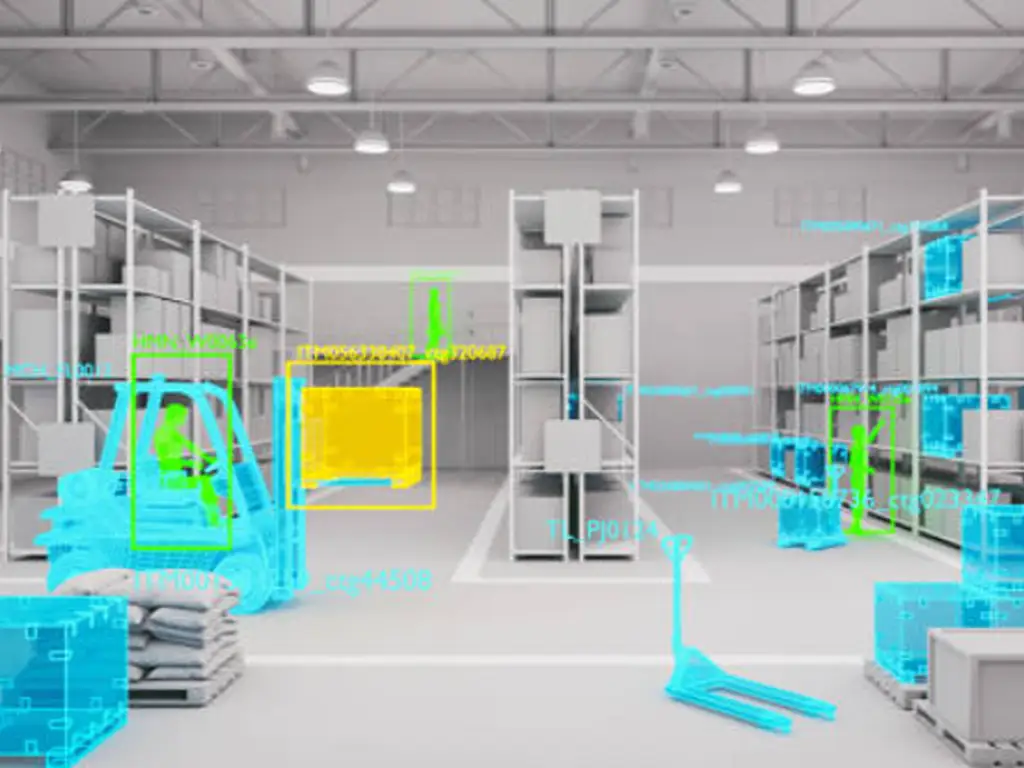

The Role of Intelligent Controls in Modern Installations

The last component of an effective installation is the brain of the system, which makes the otherwise non-responsive hardware into a responsive, energy-efficient network.

Smart Controls: Sensors and Automation

In warehouse settings, microwave occupancy motion sensors are better than conventional PIR sensors, as they provide a more accurate motion detection in a complicated warehouse.

- Obstacle Penetration: Microwave sensors have the ability to see through light barriers such as cardboard boxes or shrink-wrap as opposed to PIR. This will guarantee that movement is detected even when a forklift is temporarily covered by a pallet, and hence, there will be no sensing blind spots.

- Human-Centric Design: This will make sure that the lights become 100% bright before a worker goes on the aisle. When inactive, the system does not go off but goes to a 10 percent standby, which is safe but sufficient to save energy.

Daylight Harvesting Techniques

In the case of warehouses that have skylights or transparent screens, Daylight Harvesting is the best policy for substantial energy savings as a secondary energy-saving strategy.

- Integration:Photo-sensors are built-in and they constantly check the intensity of the natural light. These sensors can use a 0-10V dimming protocol or DALI dimming protocol to form a real-time feedback loop between natural and artificial light.

- Automation: The system has the ability to automatically turn off LEDs when natural lighting is adequate and in most cases the system saves more than half of the energy used. It is also a practice that reduces thermal stress on components thus greatly prolonging the overall working life of the system.

Conclusion: Achieving a Seamless Warehouse Lighting Installation

The combination of scientific layout, high mechanical structure, and stable supply chain makes the installation of the warehouse lighting a success. To ensure that this investment can be continued to be helpful in the upcoming decade or more, you need to have a partner with excellent history of international certifications and accurate production. Focusing on the durability of the impact at IK10 level, applying the precise optical targeting, smart control systems, and making sure that the light is distributed in the most optimal way, you will make your warehouse a working, safe, and future-proof centre. To achieve this goal, in case you are thinking about your next light project, such professional brands as WOSEN and their rigorous testing policies and reliable delivery will become the right guarantee to achieve this goal.