Introduction

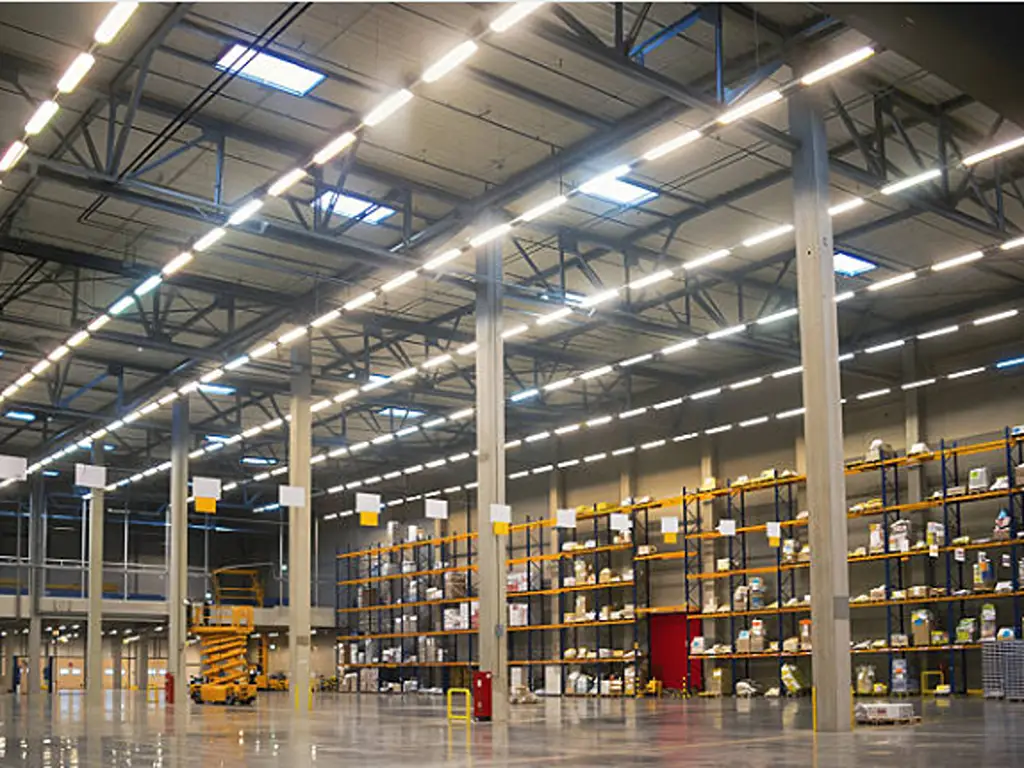

In a highly competitive business landscape, warehouses serve more than just a storage purpose – they are integral in optimizing operational functions. One of the most important components of a warehouse, which is commonly overlooked, is the lighting design. Like many other processes, warehouse lighting is complex. Conventional warehouse illumination systems are outdated and don’t satisfy contemporary standards for spatial comfort, safety, precision, and employee well-being. Furthermore, traditional lights use enormous amounts of energy, have high maintenance requirements, and need to be changed frequently.

This guide discusses the ways your business can be futuristically protected by advanced warehouse lighting, particularly focusing on LED technologies, to help you cut expenses, enhance operational efficacy, and performance. We promise to give you a detailed yet easy overview of the industry standards with respect to fixtures and practical warehouse lighting applications, so that your systems with caps and quality fixtures can withstand future changes.

Why Modern Warehouse Lighting Design is Crucial

The right warehouse lighting design can affect a company’s bottom line, employee wellness, and productivity to a profound extent. Its strategic importance can result in powerful benefits if executed systematically, and significant risks if neglected.

- Maximizing Accuracy and Operational Efficiency: Productivity is often hindered by inadequate lighting. Eye strain, slow work pace, errors, and dim spaces all have an impact on productivity. Optimal performance on a variety of tasks requires more than mere consistency; uniform illumination is crucial, especially where human eye strain is involved. Improved lighting alone can reduce retrieving picking errors by a staggering 30% and improve task completion times by 10-15%. Increased throughput and expedited order fulfillment can, therefore, be expected.

- Employee Safety and Well-Being Considerations: Accidents in industrial workplaces are often the result of dark shadows, concealed obstacles, and dark spots. Proper illumination and lighting use can reap substantial benefits. Diminished trips, slips, and falls, along with reduced human strain, are a welcome benefit for any workforce. Better lighting can go on to improve workforce comfort and alertness, which can further improve productivity. Studies support the notion and suggest that better lighting can reduce accidents by 20% in industrial settings.

- Reducing Operational Costs and Energy Use: Lighting uses up 30-50% or more of a warehouse’s energy. Using LEDs and upgrading to an energy-efficient warehouse lighting design can result in significant cost savings; LEDs alone can cut electricity costs by 50-80%. Since LEDs have longer lifespans, they also incur lower upkeep costs. Overall, the energy savings alone will yield a return on investment within 1-3 years.

- Ensuring Compliance and Preparing For The Future: Organizations such as OSHA have local governing bodies, while ISO, CIE, and IESNA serve as internationally guiding frameworks concerned with illumination and setting requirements for marking borders. Light design fundamentally achieves compliance, gaining legal safety net protection. Moreover, LED systems can be very easily changed and are easily alterable to suit new designs, layouts, and warehouse automation policies, so they are adaptable for relevance well into the future.

LED: The Driving Force Behind Modern Warehouse Lighting Design

The design of warehouse lighting systems has enabled warehouses and distribution centers to reap significant gains from the performance benefits of precision LED lighting technology. Understanding these benefits is the easiest way to see why LEDs have become synonymous with warehouse lighting.

1. Unparalleled Energy Efficiency: By definition, an LED is a Light Emitting Diode, which is a solid-state semiconductor device. LEDs emit light when current passes through them, creating a relevant electrical signal, meaning this technology is exceptionally efficient at transforming energy into light, as they do not need to waste heat to produce light. They’re able to offer unparalleled value when it comes to energy consumption, achieving a 50% to 80% reduction in energy costs.

For instance, a typical 400-watt metal halide high bay might produce around 20,000 lumens, equating to 50 lumens per watt (lm/W). A comparable LED high bay, such as Wosen’s DIMLUX series, at better than 200L/W (40,000 lumens at 200W), this LED high bay has 4 times the efficacy over traditional light, demonstrating drastic reductions in electricity. These reductions are best realized in large warehouses where the average can reach into the tens of thousands yearly, with that rapid return on investment.

2. Extended Lifespan and Reduced Maintenance: Traditional lamps typically burn out within 10,000 to 20,000 hours of use, requiring seemingly constant replacements and maintenance. However, LED fixtures outshine all forms of lighting and are estimated to last up to 50,000 hours. This durability greatly extends the maintenance schedule; unlike LEDs, bulbs need replacing through scissor lifts and specialized work in valves, with a slew of costly interventions and disruptive ‘routine’ servicing. For units equipped with LEDs, decades can pass without any need to touch the unit, resulting in cost-efficient and safer LED systems that reduce the operational work required over time. Significantly lower maintenance needs and reduced risks drastically improve safety while reducing material cost.

3. Instant On/Off and Dimmability: Unlike older systems, LEDs provide instant full brightness and eliminate warm-ups. While crucial for daylight detection systems, this capability is unmatched for advanced control systems tailored for peak work hours. The ease of dimming LEDs enables floors to adjust illuminance based on presence detection, time of day, or task specifics and change the focus, thus creating better routines for optimal productivity zones.

4. Superior Light Quality: LEDs provide superior light quality with high values of Color Rendering Index (CRI), which is generally above 80. This makes it possible to view more vivid and natural colors under LED light, which is important for accurate product identification, quality control, inspection, and safety in places that use color-coded systems. Uniform light illumination provided by LEDs is comfortable for the human eye, alleviating strain and improving visuals. Furthermore, LEDs are available in various Correlated Color Temperatures (CCT) such as warm whites (3000K) and daylight simulating (5000K – 6500K). Cool temperatures are often preferred in warehouses because they enhance alertness and visual clarity, especially in parts of high activity.

5. Robustness and Environmental Adaptability: Contemporary models of LED fixtures integrate technologies that enable them to endure the harsh conditions of the warehouse environment. With high IP (Ingress Protection) ratings like IP65, they are resistant to dust, moisture, and vibration, which ensures reliable performance even in demanding industrial environments.

Core Warehouse Lighting Standards and Regulations

The standards and requisites concerning lighting in warehouses differ across the globe. Taking into account local, national, and international legal obligations when designing lighting in warehouses is fundamental because of safety, operational effectiveness, and legal implications. These guidelines are set by numerous international and nationally recognized bodies.

Key Standards and Organizations:

- OSHA (USA): A legal requirement to have sufficient lighting that is safe and does not cause accidents.

- IESNA (North America): Suggests a lighting level of between 100 and 200 lux for most warehouse spaces and higher for more detailed tasks.

- ISO/CIE 8995-1 (Europe): Suggests an illumination level of 100 lux for general storage and increases it to 300 lux for packing and shipping areas. It is customary to use 150 lux for pathways.

- National Standards (e.g., GB50034 in China): Outlines illumination requirements set in lux tailored to the precision of goods (50 lux for coarser parts and 200 for finer parts), but vertical illumination of shelves is best set at a minimum of 50 lux.

Typical Illuminance Requirements by Area:

| Warehouse Area | Typical Recommended Illuminance (Lux) | Key Considerations |

|---|---|---|

| General Storage & Bulk Storage | 100 – 150 | Orientation, movement, basic identification |

| High-Rack Aisles (Manned) | 200 – 300 (vertical on rack face) | Clear reading of labels, product identification, glare control |

| Picking/Sorting Areas | 300 – 500 | Precision tasks, high accuracy, color rendering |

| Packing & Dispatch Areas | 300 – 500 | Detailed work, quality control, consistent lighting |

In addition to the suggested levels of illumination, other elements of lighting design are just as important, such as:

- Uniformity: The level to which light concentration in the working area and on the floor is the same, and that there is no glaring difference between bright and dark areas, which can be uncomfortable to the eyes. For most purposes, it is often recommended to have a set uniformity ratio (the ratio between the minimum brightness and average brightness) of 0.45 or more for all-purpose areas.

- Glare Control: Minimizing discomfort or disability glare is critical for safety and ergonomic comfort. Proper selection of luminaires, mounting height, and efficient light directing optical design must be done since workers’ eyes should not be looked directly at (UGR < 25 is a common goal).

- Color Rendering Index (CRI): Achieving a value of 80 or more is generally recommended for warehouses to ensure that colors are rendered accurately. This is essential in a color-coded inventory or quality inspection task.

- Flicker: The use of quality LED drivers guarantees the absence of perceptible flicker, leading to headaches, eyestrain, and even triggering seizures. Analyzing and applying all these warehouse regulations sheds light on design from a functional component to an instrument fine-tuned for operational streamlining and compliance integration.

Types of Lighting Technologies Used in Warehouses

The move to LED lighting has changed the design of warehouse lighting, with different types of fixtures designed for different applications.

LED High Bay Lights (UFO/Linear)

These are the primary choice for general warehouse illumination in high-ceiling environments (typically 15 feet or more).

- UFO High Bay Lights: High bay lights are the best UFO style that has a round shape, isn’t too big, and looks good. UFOs usually give off a lot of light, and they can serve multi-purpose functions so that open spaces are well lit. UFOs are usually very durable, and they are built with strong IP ratings, IP65, for example. DIMLUX High Output Superior LED High Bay Lights are one example. It is sturdy and offers up to 200lm/W, and offers great beam angles for open spaces.

- Linear High Bay Lights: Linear also falls under LED High Bay Lights. These are best used for rectangular spaces and aisles. They have a wide area coverage and they provide the much-needed light and visibility that a lot of standard and big areas demand.

Use In: General Storage Areas, Free Floor Space, Packing and Shipping Zones, Manufacturing Areas with High Ceilings.

LED Linear Lights/Rack Lights

Row and rack LED lights are perfect lighting tools for vertical storage shelving units. They have the property that helps concentrate light precisely on the vertical rows and narrow paths.

- Purpose-Built Optics: Include particular asymmetric or narrow beam angles (i.e., 25°x85° or 30°x60°). This optical distribution control leads to no loss of light and helps improve the illumination on product labels and along the pick path, enhancing safety and visibility.

- Mounting: For mounting, positioned in the central part of the lane, above the aisle, also in continuous lines, to provide cutout and seamless shadow-free light.

Use In: Cold storage aisle, picking and fulfillment zones, high-bay shelving, and narrow aisle racking.

LED Panel Lights/Downlights

These are designed to enhance comfort while maintaining efficiency in supplementary areas located within a warehouse complex.

- LED Panel Lights: Provide sleek and flat structural forms that emit diffused and uniformly mid-strength light. Perfect for offices and other subordinate administrative regions, including breakrooms, as well as quality control booths where the focus is placed on attentional demands.

- LED Downlights: Spotlight for angled illumination in some parts like corridors, locker rooms, restrooms, storage spaces, or particular workstations.

Use In: Office, break room, rest room, locker room, meeting room, corridor, and designated quality control offices.

Warehouse Lighting Design: From Strategy to Implementation

The warehouse lighting design must cover every detail – strategy and principles of modern technology to maximize performance, enhance energy efficiency, and add value to the warehouse.

Photometric Simulation and Design Planning

This step guarantees that the design will yield illumination results that meet performance expectations.

- Site Assessment: Gain complete knowledge of the dimensions, layout, obstructions, environmental conditions, operational flow, and requirements of the warehouse.

- Utilizing Professional Lighting Design Software: DIALux evo and similar tools enable space modeling, light distribution simulations (illuminance map generation), performance metric evaluations (lux, uniformity, glare, power density), and issue identification that could hinder installations.

- Budgeting and ROI Projections: Set attainable budgetary figures and calculate comprehensive ROI estimates to demonstrate reductions via energy expenditures, maintenance costs, and payback periods in a few projections.

Beam Angle and Light Distribution Selection

These choices have direct impacts on efficiency, visibility, and standard warehouse task completion.

- Symmetric Light Distribution: Provides a uniform, circular light spread, ideal for open floor areas and general storage (e.g., 60°, 90°, 120° beam angles).

- Asymmetric and Narrow/Extreme Narrow Distributions: Narrow and extremely narrow asymmetric distributions, such as 25 degrees by 85 degrees, are required. These provide finely focused light to tall, narrow aisles and efficiently illuminate vertical rack faces on narrow aisles.

- Impact of Ceiling Height and Aisle Width: These dimensions heavily impact beam angle selection because higher ceilings tend to require narrower beams to capture floor light, while the aisle dimensions define the optimal asymmetric beam angle.

Smart Control Systems

The acquisition of smart controls converts lighting into a flexible, dynamically optimizing efficiency resource, aiding in conserving and utilizing LEDs to their full capability.

- Motion/Occupancy Sensors: These monitors recognize the presence of people or moving vehicles. In less populated sections of aisles or corridors, lights can be programmed to gradually lower or turn off when no motion is detected, but spring back to full illumination the moment someone steps in. These actions promote energy efficiency gains, particularly in warehouses with sporadic activity. For example, in large distribution centers, areas with infrequent access can achieve up to 50-70% reduction in lighting energy consumption with appropriate sensors through dimming or switching off lights during low-activity periods.

- Daylight Harvesting Sensors: Monitor natural light, automatically adjusting artificial lights to maintain target illuminance, saving energy and providing consistent comfort.

- Wireless Control Systems: The development of wireless technologies (e.g., Bluetooth Mesh, Zigbee, and Wi-Fi) has transformed control of lighting systems from the use of cords to wireless methods. Facilitates further zoning, scene setting, remote monitoring, and the optimization of data analytics.

- Integration with BMS/WMS: Evolution in warehouse illuminations or smart lighting systems integrates wider systems within the entire building or operational system, which permits or allows for:

- Automated Lighting based on WMS Tasks: Lights in specific aisles could automatically brighten as a pick order is initiated in that zone.

- Energy Management: Use of a dedicated or centralized control for HVAC, security systems, and lighting for comprehensive energy savings.

- Predictive Maintenance: Lighting systems feeding data to a BMS can flag potential fixture failures before they occur, enabling proactive maintenance.

How Wosen Empowers Your Future Warehouse: Professional LED Lighting Solutions

As specialists in manufacturing commercial-grade LED lights, Wosen provides dependable and high-performing LED warehouse lighting solutions. Wosen gets your warehouse requirements. We don’t just sell lights; we work with you to custom-design solutions that alleviate challenges your business faces, enhance operations, and provide real ROI.

The warehouse is unlike any other setting, and we get that. Wosen incorporates brand and project requirements by offering customizable solar lighting and LED, and adaptive branded solutions, changing lights into an operational and strategic advantage.

Addressing Pain Points, Creating Value: Wosen’s Distinct Advantages

1. Customized Design Excellence: Wosen offers photometric simulation and lighting scheme design services in-house. Our qualified designers tailor lighting plans based on precise optimal light distribution with the warehouse’s specific layout and operations to avoid wasting light.

2. Superior Product Performance & Longevity: Wosen LED fixtures are designed with advanced technologies to achieve unmatched performance of over 50,000 hours of life, meaning reduced maintenance. Investment in products such as DIMLUX High Output Superior LED High Bay Lights with 200 lumens per watt efficacy will save clients on maintenance while ensuring an increase and the best return on investment. Available in multiple beam angles, giving flexibility in the best illumination placement.

3. Robustness Engineered for Harsh Environments: Warehouses are demanding environments. Wosen’s fixtures are built to endure, featuring IP65 waterproof and dustproof ratings, protecting performance and enhancing product lifespan by reducing replacement needs.

4. Simplified Installation & Maintenance: Reduced operational costs and disruptions from easy-to-install user-centric designs and minimal ongoing maintenance with Wosen’s enduring LED solutions save labor time and money.

5. Advanced Functional Upgrades & Unrivaled Warranty: Wosen LED fixtures include multiple brightness adjustments, high CRI, and color modes with proper color temperature. Integrated light sensor functions with scene presets enable dynamic energy optimization. Unmatched peace of mind for your investment is provided by robust 5-7 year warranties—industry-leading, affirming our confidence in product quality.

By partnering with Wosen, you’re not just purchasing LED lights; you’re investing in a future-proof warehouse lighting design solution that promises enhanced safety, boosted productivity, and significant, sustainable cost savings.

Conclusion

Controlled efficiency and precision are determining factors of any given era, and optimized warehouse lighting design is a major operational advantage. Modern LED technology and smart lighting solutions are the cutting edge to lower operational costs, improve employee wellbeing, and protect environmental resources. This guide aims to shed commensurate value to your company’s monetary value.

As discussed, a carefully planned light approach is paramount to operational flow, ensuring efficiency, significant energy conservation, and creating a workspace that is indisputably safer. Moreover, we highlighted the essential benchmarks and types of lighting fixtures, alongside state-of-the-art equipment like photometric simulations, smart controls, and advanced technologies that form the basis of an efficient illumination strategy.

Your infrastructure requires thoughtful decisions in order to increase your productivity and adapt your business to future changes. Using advanced lighting designs and premium warehouse lighting fixtures can improve productivity, safety, reduce costs, and increase sustainability.

Here at Wosen, we specialize in custom design solutions for professional LED warehouse lighting and are committed to product excellence with industry-best guarantees. We help businesses achieve practical operational efficiency and polish through unparalleled illumination. Our team is ready to transform your warehouse illumination. Don’t get left behind by outdated warehouse lights and contact Wosen today to begin your journey to a brighter, smarter, and more profitable tomorrow.