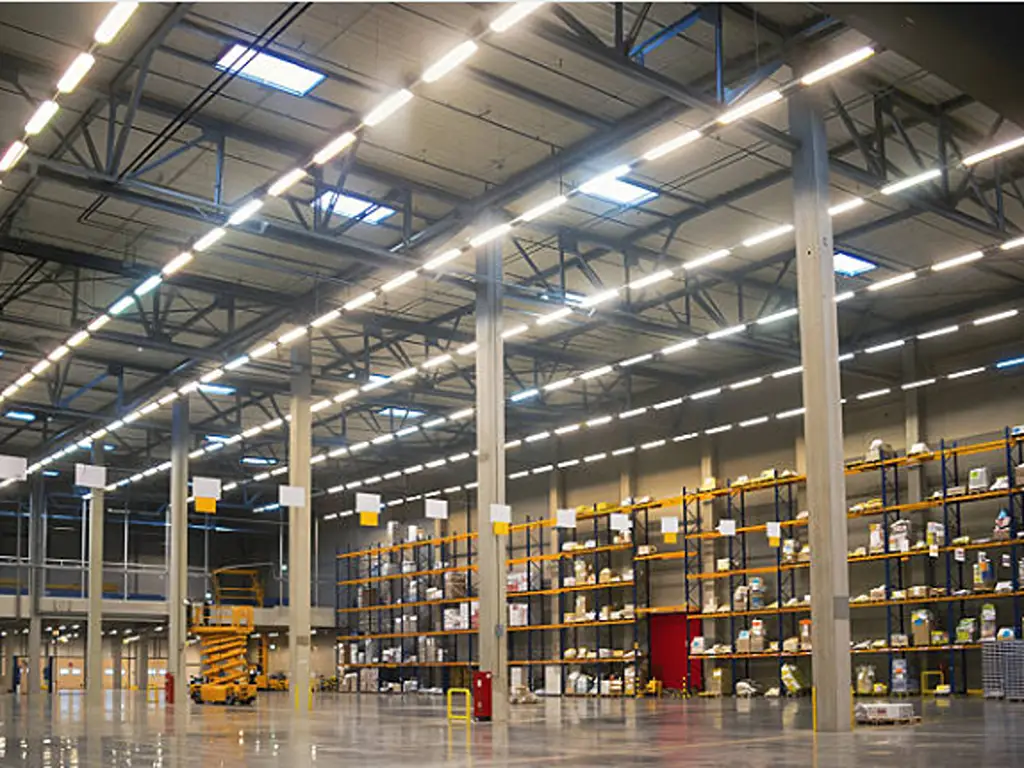

Good warehouse lighting does far more than help people see; it lifts output, keeps workers safe, and plays a crucial role in even raising profits. In the past, many buildings made do with patchy HID or flickering fluorescent fixtures. Thankfully, today’s industrial lamps are a whole lot better.

The first step in riding that shift is knowing the various types of warehouse lighting fixtures and light fixtures that now fill a warehouse. Proper lighting with LED warehouse lighting fixtures has become the clear go-to choice for warehouses due to their minimal maintenance requirements. They deliver energy savings and a long life that older bulbs simply cannot touch. This article walks you through the newest warehouse lighting styles and shows why shifting to LED pays off. After all, the right lights can slash power bills, speed up work processes, and protect every person on the floor.

From HID & Fluorescent to Modern LED

For years, the available types of warehouse lighting were limited to legacy technologies like High-Intensity Discharge (HID) and fluorescent lamps, each presenting significant operational issues. Metal Halide (MH) and High-Pressure Sodium (HPS) lamps drank power, wasted heat, and took so long to brighten that work flowed unevenly. Fluorescent bulbs seemed better, but they flickered in cold temperatures, burned out quickly when flipped on and off, and posed a hassle at the dump because of their mercury. Enter Light Emitting Diode (LED) lights, a clear leap forward with a long lifespan. Built as sturdy, solid-state units, LEDs run cooler, last far longer, provide substantial cost savings on energy costs, consuming significantly less energy, and give managers tight control over brightness and color, pushing warehouses toward smarter, more reliable lighting.

| Feature | LED (Light Emitting Diode) | MH (Metal Halide) | HPS (High-Pressure Sodium) | Fluorescent (T8/T5) |

| Efficacy (lm/W) | 130 – 200+ | 75 – 100 | 80 – 140 | 90 – 105 |

| Lifespan (Hours) | 50,000 – 100,000+ | 10,000 – 20,000 | 16,000 – 24,000 | 20,000 – 30,000 |

| CRI | 80 – 95+ | 65 – 85 | 20 – 30 | 75 – 95 |

| Warm-Up Time | Instant | 5 – 15 Minutes | 3 – 5 Minutes | 1 – 3 Minutes |

| Dimming Capability | Excellent, Standard | Limited, Complex | Very Limited | Limited, Requires Special Ballast |

| Energy Wasted | Minimal | Significant | Significant | Moderate |

| Maintenance Cycle | 10-20 Years | 2-4 Years | 3-5 Years | 4-6 Years |

This table doesn’t just show numbers; it illustrates a clear and compelling case for leaving the costly, high-maintenance technologies of the past behind and embracing modern types of warehouse lighting.

Matching Key LED Fixtures to Your Space

Choosing to upgrade to LED is the first and most important step.But dont assume the term LED is a one-size-fits-all fix. Good lighting requires matching each fixture to the exact needs of every area in your building. Picture the process not as buying bulbs, but as picking the right tool for a job-from desks to aisles and machines to break rooms.

- UFO High Bay Light:In most modern warehouses, the go-to fixture is the UFO High Bay lights. Shaped like a small flying saucer, this light blends smart cooling with sharp optics. Its die-cast aluminum body pulls heat away from the LED, so the lamp lasts far longer. Because it hangs from a single point, the mounting job is quick and secure. With wide beams that stretch across open spaces and areas higher than 20 feet-about 6 meters-its ideal for bulk racks, receiving and shipping docks, and staging zones. Uniform, shadow-free light lets workers and forklifts move confidently and productively throughout the whole space.

- Linear High Bay Light: Where the UFO High Bay rules wide, open rooms and warehouse environments, the Linear High Bay tames narrow aisles and corridors. In buildings packed with tall racks and high ceilings, these slim, box-like lights become essential in the implementation of high bay lighting. Their smart optics throw a long band of light that washes down shelf fronts and aisle floors but stops before reaching rack tops, saving energy. That’s vital during picking and put-away, where workers need speed and spot-on accuracy. By guarding every label, barcode, and pick slip from the top shelf to the bottom, Linear High Bays keep operations moving smoothly.

- Vapor Tight:Yet not every warehouse area stays neat and dry. Think wash-down bays, chilly coolers, or food prep zones that face steam, splash, dust, and corrosive cleaners. In those spots, the Vapor Tight Fixture steps in like a metal shield. Gasketed and sealed tight, these fixtures score high IP grades-IP65 or even IP67-showing they shrug off water jets and grit. So, even in tough, damp corners, your lights keep shining, matching the toughness of the rest of the line.

WOSEN’s Solutions for Every Warehouse Zone

Upgrading lighting is a big investment, and facility managers cannot afford failures or delays. At WOSEN, we built our company to shield you from those risks. Inside our 30,000-square-meter plant we do it all, from die-casting ADC12 aluminium housings to the final assembly. This in-house approach isn t just bragging; it comes with a full five-year warranty, so you know we stand behind every light.

Because we handle every step, our fixtures perform better in the spaces you choose. Take the DIMLUX Series; its heavy-duty build suits the high ceilings and open bays of any warehouse. For corridors or special-use zones, the FLATLUX Series meets the toughest certification. By testing every model in our own labs, we ship lights you can count on, removing guesswork from your upgrade.

Decoding Specs: Lumens, Efficacy, CCT & CRI

If you want to pick lighting fixtures with real confidence, you need to learn the basics of light. Sticking to old rules of thumb like wattage can cost you time and money. In the world of LED, quality is measured by different numbers. Get to know those numbers, and youll see real value.

Start by separating Lumens from watts. Lumens tell you how much light comes out. Watts show how much power the fixture pulls. With older bulbs and fluorescent lights, the two figures moved in lockstep, but LEDs broke that link. Now the most telling metric is Luminous Efficacy, stated in lumens per watt (lm/W). You can picture it as the miles-per-gallon rating for light. A lamp rated at 160 lm/W gives you twice the glow of one at 80 lm/W using the same energy. Keep that figure in mind, and you’ll spot savings before the first fixture is hung.

Next up is Correlated Color Temperature, or CCT, and we measure it in Kelvin (K). CCT tells you what color the light looks, from warm yellow to cool blue. A low CCT near 2700K gives that cozy, candle-like glow you get from old-school incandescent bulbs; great for living rooms, but not much use on a factory floor. For warehouses and big work areas, the sweet spot sits between 4000K and 5000K. A 4000K lamp spills out neutral white light, while 5000K offers a bright, almost outdoors white that feels like midday sun. Workers under that cooler glow tend to stay alert, strain their eyes less, and concentrate better, so it is the go-to choice when focus and productivity really matter.

Finally, the Color Rendering Index, or CRI, may be the one feature people overlook most often. Measured on a simple scale from 0 to 100, the number shows how closely a bulb reveals a things true color compared to daylight. Old low-pressure sodium fixtures, sitting around 20 or 30, washed everything in dull orange, hiding the red box and brown box so well you could miss the difference. Swap those for a modern LED rated above 80, and colors snap into focus. That bump in clarity isn t just about looking nice; it touches the core of workplace safety. Good CRI lights help the staff read a red warning label correctly and let a forklift driver spot a puddle instead of rolling through it. Its like trading a fuzzy snapshot for crisp high-def video-you see exactly what’s in front of you.

Maximizing Your ROI with LED And Smart Controls

An LED lighting upgrade isn’t just an expense; it’s an investment that starts generating a predictable, high-yield return the moment it’s switched on. This tangible Return on Investment (ROI) comes from three distinct pillars of savings:

- Direct Energy Savings:

This is the biggest pillar. Picture a 100,000-square-foot building swapping 150 old 400-watt Metal Halide lights for 150-watt WOSEN LED high bays. The outdated setup draws 60,000 watts; the new one pulls only 22,500 watts-a drop of 62.5 percent. Running 12 hours a day, every day, and paying around 0.15 per kilowatt-hour, the switch saves more than 24,600 a year.

- Near-Total Elimination of Maintenance Costs

A metal-halide (MH) bulb usually burns out after about 15,000 hours, so in a busy workplace you swap them every three to four years. That swap isnt only the 50to50to100 you pay for the lamp and ballast; you also have to rent a lift, redirect staff, and hope the lights shuffling doesnt halt production. Add all that up, and the true cost can soar past $200 for each fixture. An LED housing, however, lasts roughly 80,000 hours, which wipes away that headache and expense for more than a decade. Across our 150-fixture site, going LED saves at least $30,000 in deferred maintenance bills.

- Utility Rebates and Incentives

Many energy companies offer substantial rebates for facilities that install high-efficiency, DLC-listed (DesignLights Consortium) products. These programs can offset the initial project cost by 20-50%, drastically shortening the payback period and boosting your overall ROI.

But the savings do not end there. By integrating smart lighting controls, you can amplify these returns even further. Think of smart controls as an intelligence layer that ensures not a single watt is wasted. Occupancy sensors can dim or turn off lights in aisles that are unoccupied for a set period, while daylight harvesting sensors can automatically dim fixtures near skylights or windows when sufficient natural light is present. This intelligent automation can easily add another 20-40% in energy savings on top of the efficiency gains from the LEDs themselves, turning a great investment into a truly brilliant one.

FAQs About Types Of Warehouse Lighting

Navigating the complexities of an LED lighting upgrade and the various types of LED lighting solutions for warehouses can naturally prompt several important questions. Here are concise answers to a few common queries related to your warehouse’s specific needs:

- Q: How do I determine the right number and placement of LED lights for my warehouse?

A: You actually need a lighting plan, often called a photometric study, that looks at your ceiling height, layout, and the work being done. Reputable manufacturers like WOSEN can provide design assistance to ensure optimal coverage with the chosen types of warehouse lighting, including an appropriate type of lighting for your specific lighting needs.

- Q: What is the typical payback period for an LED warehouse lighting upgrade project?

A: Most jobs break even in 1 to 3 years because older setups waste power and add upkeep costs, while LEDs slash both. Higher kilowatt rates and long operating hours can speed returns even more.

- Q: Are there commonly available rebates or other financial incentives for upgrading to LED warehouse lighting.

A: Yes. Your local utility or even some state programs hand out cash rebates or tax credits when you swap LEDs. Double-check with those agencies, so the upgrade costs you less upfront and ramps up savings faster.

A Strategic Asset, Not Just an Upgrade

The path forward is clear. Choosing to upgrade to efficient lighting in your warehouse to efficient warehouse lights and lighting solutions is a turning point, moving you away from old, dim, expensive, and hard-to-maintain fixtures to a brighter future packed with safety, savings, and superior energy efficiency while providing adequate illumination and reducing operational costs through smart energy use for efficient operations. We’ve watched the tech world shift, leaving behind the harsh glow of HID lamps and stepping into the focused, efficient light of today’s LEDs. Along the way, we’ve broken down the specs that really matter, spotted the smoke-and-mirror talk, and put hard numbers on the big return on investment that’s waiting for you in terms of reduced energy consumption.

So, yes, swapping bulbs is the start, but its far from the whole story. Its also a smart upgrade to your most important resource-your people and the work they do. Good lighting helps them move, see, and think more clearly, cutting errors and accidents. Its an easy way to shrink power bills, trim upkeep, and give your business the edge it needs to win. With this insight in hand, you arent just a manager or an owner; you are the planner of a brighter, busier, and more profitable tomorrow.